For several years now, the Pet Food Industry has experienced numerous recalls due to Salmonella. This typically is the direct result of contaminants in the ingredients, and when it comes to Salmonella the culprit of this contamination is typically chicken fat. When you consider that 44% of pet food recalls from 2017 to 2023 were caused by Salmonella, something the FDA has set a zero tolerance level for, it’s imperative that pet food manufacturers consider the ingredients in their formulations to avoid this risk.

The FDA and Zero Tolerance for Salmonella

In 2013, the Food and Drug Administration established a policy suggesting pet food manufacturers adhere to guidelines calling for zero presence of Salmonella in their products. This was due to a number of recalls that had taken place in the years before in which humans had developed severe illness as a result of coming into contact with pet food. In healthy pets, the risk of illness is low. Humans however, those who feed their pets and can have residue left on their hands or other areas, are quite susceptible to illness and even death from Salmonella. The FDA responded with this zero-tolerance policy for pet food, a standard that is much stricter than that of farm animal feed. Regulators are out in the field, testing products on store shelves and informing pet food manufacturers when they find instances of Salmonella to prompt a recall. That’s a call no manufacturer wants to get.

Yet even with these stringent regulations, inspection practices, and notifications in place, pet food recalls due to Salmonella contamination persist. From 2017 to 2023, the FDA reported 126 pet food recalls. 56 of those recalls were due to Salmonella. This signals that many pet food manufacturers have yet to adjust a key ingredient that is a primary contributor of Salmonella contamination: chicken fat.

Using Gold Shield Refined Chicken Fat Can Help You Eliminate Salmonella Risk

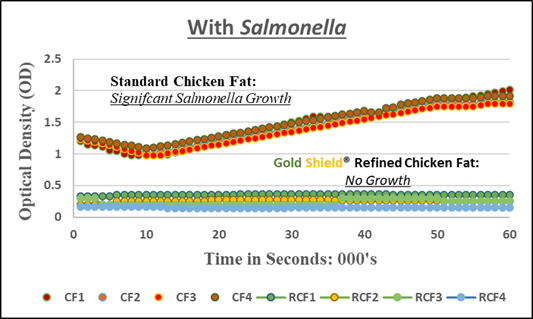

At Pet Food Solutions, we’ve performed extensive research which has found that pet food manufacturers who use our Gold Shield® Refined Chicken Fat eliminate the risk level of Salmonella contamination they face when using regular chicken fat. This is important because chicken fat is applied to kibble after the high temperature extrusion process which generally kills biological contaminants such as Salmonella. In absence of such a high temperature treatment, Salmonella can grow aggressively in standard chicken fat if it’s present in the ingredient, creating a very real danger to human pet owners.

The proven performance of our Gold Shield® Refined Chicken Fat lies in our proprietary refining process:

- We begin with standard chicken fat, which may contain contaminants such as Salmonella, trace metals, debris, and other impurities. Not only do these elements impact the quality and stability of your pet food, but they can also create challenges on the production line and increase your risk of a recall, a situation that can damage your brand.

- We extract the impurities through a proprietary process that removes all of the contaminants that can be harmful to your product, operations, and position in the market.

- We deliver a finished product of clean, clear, Gold Shield® Refined Chicken Fat that removes virtually all contaminants and offers an ingredient with no risk of Salmonella growth, as demonstrated in the chart above.

The image above shows you what we start with, what we remove, and the pure product we deliver to you. It’s an ingredient you can count on to deliver safety, stability, and greater value with 100% usable product all while enhancing operational efficiency and creating more precise formulations. It’s better for your brand, and better for your peace of mind.